Your pioneer for AI-supported production

At PCB Arts AI, we develop individual solutions for retrofitting and optimise production processes with state-of-the-art machine vision technology. Our customised hardware bundle combines powerful AI hardware with industrial cameras from leading manufacturers - perfectly tailored to your application. Supplemented by intelligent evaluation software customised to your production, we create efficient and future-proof systems.

With our expertise in AI-supported image processing and embedded technologies, we develop solutions that guarantee maximum precision and quality. We accompany you personally through the entire process - from the initial idea to successful implementation.

Quality losses cost European industry billions

Every year, every manufacturing company in Europe loses an average of €85,000 due to faulty products and rejects - costs that could often be avoided!

Manufacturing companies

in Europe, which produces billions of different products every day. From the plastics industry to the wood and metal industries.

Scrap rate

are produced on average - most probably also by your company. This means that every 34th product never leaves your production facility.

Euro

are literally produced ‘for the bin’ every year. An enormous burden for companies, the economy and Europe as a production location.

Advantages of AI compared to classic machine vision

Traditional machine vision systems often require the manual writing of complex algorithms, which can be time-consuming and costly. With AI-based solutions, this step is eliminated. Instead, neural networks are trained with existing data, which significantly reduces development time. What this means for you:

- Faster set-up: Quality assurance is ready for use in just a few hours.

- Reduced costs: Less development effort leads to lower implementation costs.

- Adaptability: AI solutions work reliably under different lighting conditions.

Your benefits of working with PCB Arts AI

Offline Machine Vision - 100% data secure

Our solution processes all images directly on the Edge device supplied - without any cloud or internet. Your production data therefore stays where it belongs: with you.

Customised solution in just a few weeks

Every day without machine vision costs you productivity. With our standardised process, your optical solution is installed within a few weeks and seamlessly integrated into your machine.

Minimum effort - maximum efficiency

We only need 4 hours of your time! Thanks to our optimised workflow, we can implement your machine vision solution quickly and easily - with minimal intervention in your operations.

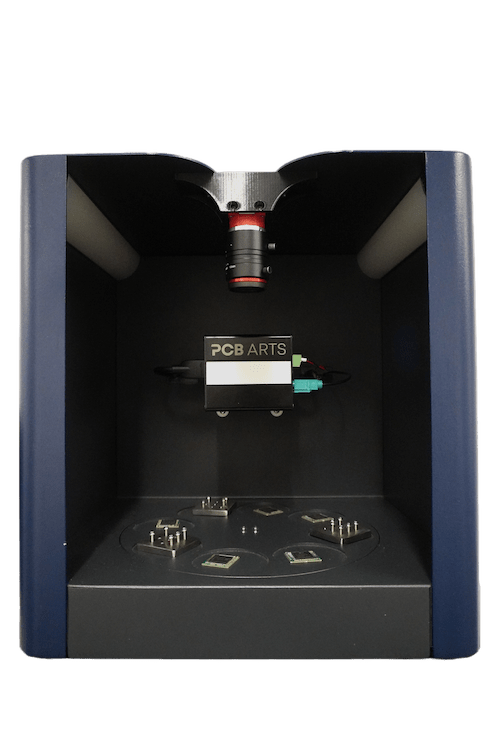

Our machine vision bundle for seamless integration

After we have analysed your requirements and defined relevant KPIs in a joint discussion, we will then put together a customised machine vision solution for you - consisting of lighting, camera, edge AI computer and neural networks. The hardware is delivered directly to you and can be easily integrated into your production.

Your Machine Vision bundle includes:

- Industrial camera & matching optics

- Light for local lighting

- Edge AI computer for local processing

- Optional: Touch screen for easy set-up

Our workflow

Goal definition

Together, we identify the central KPIs for your quality assurance. We then select the appropriate sensors, the edge AI computer and the optimum lighting. On this basis, we create a customised offer.

Integration of the Machine Vision Bundle

As soon as your Machine Vision bundle arrives, it can be integrated directly. For the initial setup and training using your products, we need one-time access via WLAN.

Training the neural network

The system processes the relevant data and trains the neural network to recognise anomalies. In this way, deviations in production are recognised - perhaps even completely new errors that were not previously noticed.

Proof of Concept

In a KPI test, we check the performance of the system under real conditions. We then evaluate the results together and define possible optimisation steps.

Deployment

After a successful proof of concept, the system is fully integrated into your production line. From now on, you will benefit from AI-supported quality assurance in live operation - including automatic error documentation.