Vapor Phase

One & Two

The Vapor Phase One offers development engineers as well as small to medium sized prototyping service providers one of the gentlest soldering processes in the industry. The Vapor Phase Two adapts this soldering process and is perfect for small batch production. In contrast to infrared or convection processes, assemblies with high thermal mass, fine pitch structures or temperature sensitive components can be processed without any problems.

Go to shop

Hi, I’m Yannik, and I’m the person responsible for our Vapor Phase Products. Whether you’ve got questions, feedback, or just want to chat about how we can make our products even better, I’m here for you.

Don’t hesitate to reach out — drop me an email at

A short introduction to vapor phase soldering

Vapor phase soldering - also called condensation soldering - is based on similar physical principles to a heat pipe. An inert liquid is brought above its boiling point, causing a vapor phase to form just above the surface. This liquid is a specially developed medium called Galden® that boils between 230 °C and 240 °C, depending on the type. This newly formed vapor transports energy from the heat source to one or more "heat sinks". In this case, these heat sinks are your PCB, your components and the applied solder paste.

The vapor condenses on the cooler surfaces first, so it transports a greater amount of energy to those areas and gently heats your board. The solder paste melts as soon as your PCB reaches the appropriate temperature. Also, the maximum temperature it can reach is limited by the boiling point of the Galden®.

- Fast temperature profiles: The design of the Vapor Phase One and Two allows the user to run fast temperature profiles using a height-adjustable PCB lift.

- Custom soldering profiles: Our vapor phase soldering systems can import individual soldering profiles via an SD card. Based on these profiles, heating power and lift position are adapted to different solder pastes and PCB technologies.

- Quick Cool: This feature shortens the process time and ensures minimal loss of Galden® when the board is removed.

- Anti Condensation: With the vapor phase technology, the soldered assembly is generally covered with Galden® residues. Our assembly is kept at a temperature of 120 °C after the soldering process, thus leaving hardly any residues.

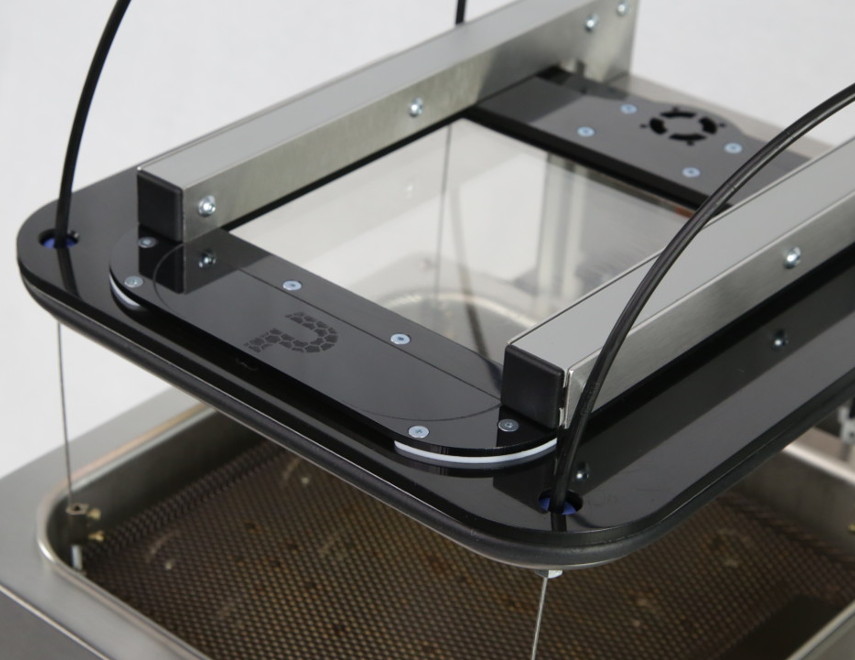

- Lifting lid: The lid to the process chamber lifts automatically to simplify the insertion and removal of PCBs. This also helps to preserve the heat transfer medium.

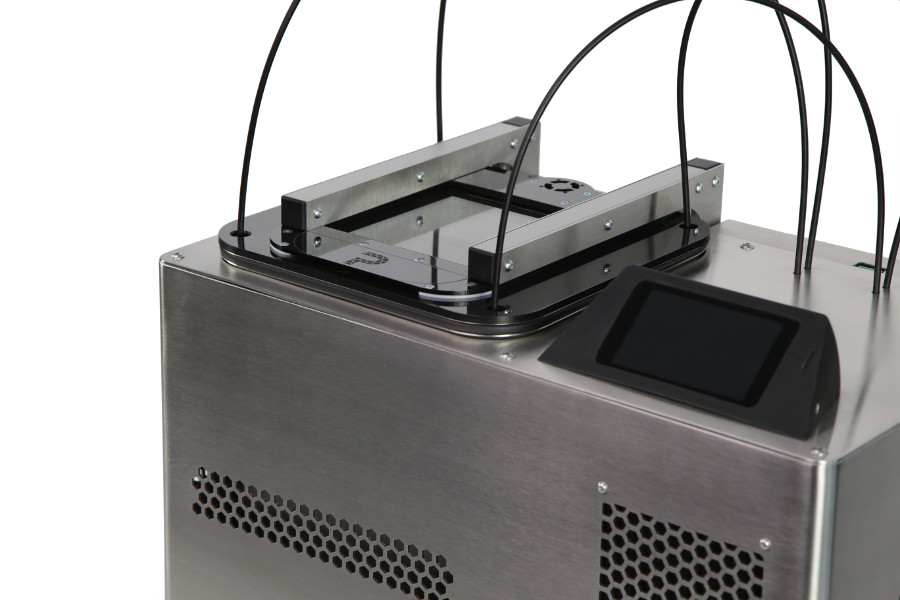

- Viewing window: In addition to a screen that displays real-time temperature data, the Vapor Phase One & Two features a viewing window with internal lighting that allows you to see into the process chamber.

- Safety: The Vapor Phases have a variety of safety mechanisms implemented in both software and hardware to ensure safe operation and soldering process.

- Open Source Hardware: We published the source code of the firmware as well as schematics and construction files in our GitHub repository PCB-Arts/vaporphaseone.

The automatic lift for perfect soldering results

The Vapor Phase One & Two is equipped with an automatically adjustable lift that dynamically adapts to the configured temperature profile, enabling precise temperature control on the PCB. Additionally, the process chamber features an integrated cooling circuit that creates different temperature zones within the chamber. The combination of height adjustment and heating control ensures that the temperature profile is maintained with high accuracy. Unlike systems without an automatic lift, this allows for precise control over the duration of the critical TAL (Time Above Liquid). This significantly improves soldering quality and ensures reproducible results. The Vapor Phase One & Two thus offers a well-thought-out solution for precise and reliable vapor phase soldering.

Specifications

| Model | Vapor Phase One | Vapor Phase Two |

| Dimensions | 495 x 650 x 320 mm | 627 x 650 x 407 mm |

| Maximum solder area | 200 x 185 mm; height: 60mm | 300 x 335 mm; height: 60mm |

| Power input | max. 1100 W | max. 2200W |

| Operating voltage | 115 / 230 VAC (60 / 50 Hz) | 115 / 230 VAC (60 / 50 Hz) |

| Environment temperature | 15 °C ... 35 °C | 15 °C ... 35 °C |

| Geographical altitude | max. 2000 m (above sea level) | max. 2000 m (above sea level) |

| Weight | 22 kg | 35 kg |

| Housing | Stainless steel | Stainless steel |

| Cooling | Enclosed water cooling with 4x fan | Enclosed water cooling with 6x fan |

| Boiling temperatures heat conduction media | 135 °C ... 240 °C (e.g. Galden© LS 230) | 135 °C ... 240 °C (e.g. Galden© LS 230) |

| Quantity of Galden | approx. 1kg | approx. 2kg |

| Amount of used electrode per soldering cycle | 0.49 ml | to be defined |

| Data interface | SD card | SD card |

| Screen | 4 inch capacitive touch screen | 4 inch capacitive touch screen |